OUR CONTINUED ADVANCEMENTS IN MODERN ENGINEERING AND METICULOUS CRAFTSMANSHIP PRODUCES WOOD BATS WITH GREATER BALANCE, UNMATCHED POWER, AND OUTSTANDING FEEL.

OUR CONTINUED ADVANCEMENTS IN MODERN ENGINEERING AND METICULOUS CRAFTSMANSHIP PRODUCES WOOD BATS WITH GREATER BALANCE, UNMATCHED POWER, AND OUTSTANDING FEEL.

Only the hardest of the hardwoods, grown in regions of the United States that produce the absolute best Rock Maple and Yellow Birch available. Only the straightest grained logs with virtually zero defects in the stock will be used in MaxBat wood bat production.

Rock Maple continues to be the most popular wood species used for bat production, and at MaxBat, we only use the best. Because maple is such an extremely hard and dense wood, players often comment that the ball jumps off the barrel of their maple bat like no other. Maple creates bats that are extremely hard, with little or no flex.

Yellow Birch is a fibrous hardwood that many players prefer because in their words “is the perfect combination between Maple and Ash”. This hardwood is a shade lighter than its maple counterpart, which allows us to utilize this species when turning full barreled bats that require a lighter weight.

MaxBat wood bats are precision designed to be stronger, last longer, and produce better results than any other wood bat in the game of baseball.

HANDLE

MaxBat handles vary in diameter, from thin, medium, or thick. Thin handles will shift weight to the barrel end. The most common diameter handle is 15/16" and is categorized as Medium.

KNOB

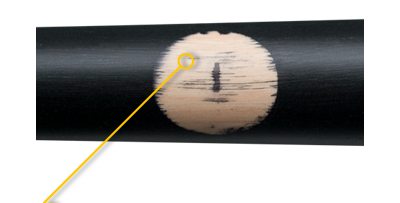

Each knob varies slightly, and will also impact a bat’s balance. More flare at the base of the handle where it meets the knob will make the bat often feel more balanced and give the batter more bat control.

WEIGHTS

We use countless mathematical formulas to pinpoint the desired weight that you've requested for your custom MaxBat. When choosing your weight, we recommend that you opt for no lighter than a -2 with a cupped end. This will give your bat more pop and durability, ultimately giving you more of an advantage at the plate. For more information on weight drops, check out our blog for help.

LENGTHS

There are a variety of lengths that you can choose from when designing a wood bat. The most common is 33" for players 16 years and older. The majority of professional players will use 33.5" and 34". This is an important feature, because you don't want to swing a bat that is too long for you to control.

BARREL

The business end of the bat. You can choose from 3 different barrel sizes when building your custom model. But what size should you choose? Medium barrels utilize harder/stronger wood, and lend to a more balanced model. XL barrels (because of their overall mass) require a lower density piece of wood to achieve your desired target weight. The barrel size is completely up to you, but know that you get the best piece of wood when choosing a model with a Medium barrel, as opposed to a Large or XL barrel.

BONE HARDENED

One of the finishing touches that we add to each of our wood bats is our patented bone hardening process. Your MaxBat will go through our custom engineered barrel compression machine, increasing and maximizing the hardness of the wood. Harder wood = greater results.

MaxBat wood bats are precision designed to be stronger, last longer, and produce better results than any other wood bat in the game of baseball.

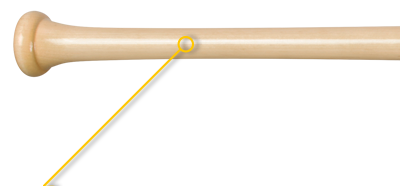

In 2009, MLB mandated that all Maple and Birch bats, destined for a pro player, needed to pass an ink-spot test. When the ink is placed on the bat handle 12"-14" from the knob, it bleeds into the non-visible tangential grains. The straighter the grain, the stronger the wood. The Major League acceptable "grain slope" is 3 degrees or less. All MaxBat Maple and Birch Pro Series bats pass this test, and our acceptable grain slope is no more than 2 degrees.

This unique feature is an available option for all of our custom build MaxBats, and can be easily added by you with just the click of a button. The flared design of the X-Knob helps protect the hamate bone from bruising, and greatly increases the bat's balance. Because of the shape, and where it comes in contact with your lower hand, the X-Knob can ultimately increase overall bat speed too.

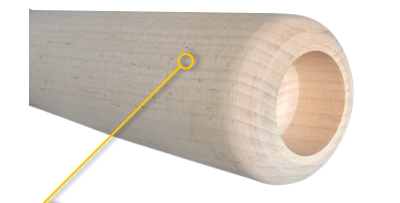

When you choose to design your custom MaxBat with a cupped end, we can utilize harder/denser wood that will translate into more energy put into a batted baseball. By cupping your MaxBat, this will also slightly shift the bat's weight towards the center, making it feel more balanced.

When you receive your MaxBat in the mail and open the box, you will immediately realize how much work, effort, and time we put into precision crafting a wood bat just for you.

The process of making a MaxBat starts by closely monitoring our hand selected Rock Maple and Yellow Birch billets in today's technologically advanced wood drying equipment. Our unique procedure ensures that the wood will be more stable and consistent than wood that is heat kiln dried. Each billet is then individually tested for moisture content, weighed, measured, and sorted using mathematical formulas that predetermine which billet is best suited for each particular MaxBat model. This extra attention to detail helps insure that the MaxBat you order is the correct weight and balance point you desire prior to production.

After the perfect billet is selected for your wood bat, it is then turned by one of our high performance precision lathes to the appropriate bat shape and size according to your order specifications. It is then weighed again, goes through an ink-spot test to measure straightness of grain, and thoroughly inspected for any visible flaws.

After passing its second inspection, your MaxBat is sanded silky smooth with two passes at the sander. It’s then weighed again, inspected a third time, and cupped. Now off to the experienced personnel in our climate controlled and air-filtered staining/finishing room. Each wood bat ordered with a custom color receives exceptional care, as our staff meticulously hand applies premium wood stains to ensure proper color penetration and evenness to bring out the beauty of the wood and bring your MaxBat to life.

After allowing the stain to properly dry, each bat passes through another thorough inspection before receiving its first of two or three coats of clear finish in our robotic sprayer. We spray your bats instead of dipping them to reduce unnecessary weight that can be added when dipping, and will give your personalized bat the MaxBat trademark finish. 60 passes in the bone hardening machine, then off to the laser engraver before it’s boxed and shipped to you. You’ll be abusing baseballs before you know it.